We have noticed the article relating to Sewer Pipe Relining below on the net and felt it made perfect sense to write about it with you here.

Intro

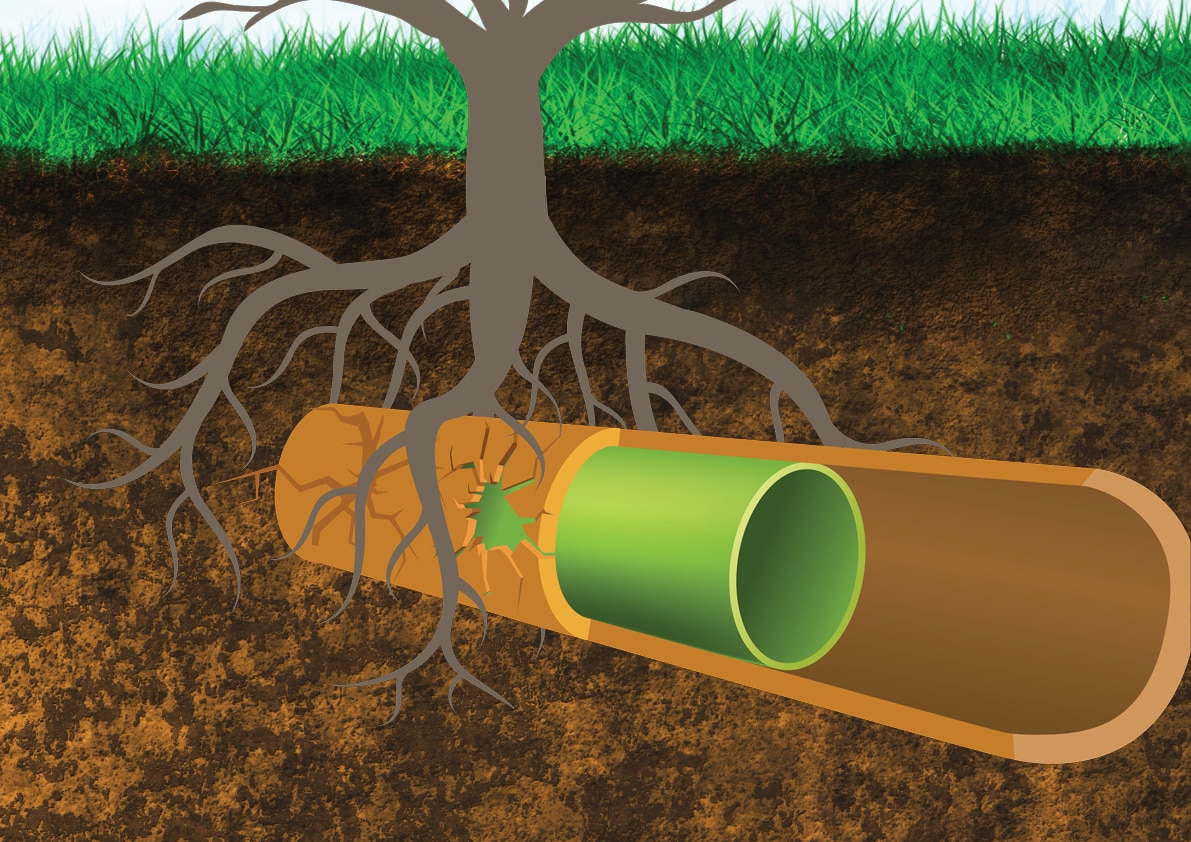

Repairing damaged pipes does not require excavating deep into your sewer lines and also trying to change them any longer. Fortunately for home owners, leaving your yard untouched while placing the damaged pipes in a far better condition is currently feasible. You might be wondering how. Well, Pipe Relining, naturally.

What is Pipeline Relining

Pipe Relining is a means of fixing damaged pipes without excavating. Instead, using a technically advanced technique called Cured in Place Piping (CIPP). The CIPP technique includes repairing a pipe from the inside by utilizing an unique material, which cures with time, creating an even stronger pipeline throughout its process. While Pipe Relining is a great approach for pipeline repair service, only a professional plumber can suggest this damage repair service technique.

The trick to efficient Pipeline Relining is developing a more powerful pipeline by injecting material in the damaged pipeline utilizing a resin felt tube. Developing a more powerful pipe is just possible when the material remedies, lasting a long time.

5 Advantages of Pipeline Relining

Pipe relining is unarguably a much better choice contrasted to the conventional excavating approach. It comes with some benefits, that makes it a preferable alternative for all pipeline repair service conditions. These are several of the advantages of pipe relining;

The expense of pipe relining is relatively reduced. Since no concrete penetration or trench digging is required, you don't need to bear the cost of durable equipment, replenishing trenches, as well as cleansing the workspace.

Relining takes little time to be completed. No additional manpower is required as well as the whole process is easy, particularly when it is being done by a specialist plumbing solution. Managing hard to reach areas is additionally easier utilizing this technique.

The resin gives an additional coating for your weak pipelines, leaving you with a two-in-plumbing unit. The epoxy material tends to be more powerful than the originally installed pipeline.

Unlike the conventional trench digging process, the opportunities of mishaps caused by a disrupted floor surface are dramatically reduced. Owners can relocate openly without disrupting the fixing procedure as well as vice versa.

The epoxy liner has a smooth surface and is free from blockages that lower the circulation of water. After relining your pipes, be anticipating a much better and also smoother water circulation.

Exactly How is Pipe Relining done?

Prompt pipe fixing is necessary in reducing the intensity of the damages. The good news is you can obtain your pipes fixed in the space of 24 hours by simply reaching out to our emergency plumbing services. The whole process is quick and also not as difficult as the conventional repair service procedure.

Below is a detailed process in relining of pipes;

Carefully observing the level of pipeline damages is the first step in pipe relining. The Forced Electron Drip Area equipment is utilized to closely evaluate your plumbing system for damages and also clogs. By doing this, coming up with a service is feasible.

The pipeline is cleaned up and all blockages removed to allow for simple water circulation. Afterward, the pipeline wall surfaces are gotten ready for resin application making use of a high-pressure water jet.

The size of your pipelines is then filled with epoxy material, which develops the more powerful pipe after curing. This step gets more difficult when handling T-sections.

Treating can be carried out in two methods; leaving it to heal by hand or accelerating the procedure by using hot water. Either method functions - it simply depends on just how swiftly you desire the lining treated.

Junctions are removed conveniently utilizing robotic cutters. Examination pits can only be cut using surface-level cutters or mills.

Final examination

Our pipe relining solutions guarantees that all relined pipes are completely checked making use of a drainpipe inspection cam. The last inspection consists of testing to see if relined pipelines are completely sealed.

Last Verdict

You can never go wrong with pipe relining. Conserving all that money and energy spent on excavating trenches certain feels great. Do not hesitate to call our specialist pipe relining solution that keeps your whole plumbing device in the most effective problem possible.

Remember, acting promptly is the only means to lower the effect of your pipe damage. Even more damage indicates even more price to sustain.

Pipe Relining is a means of fixing broken water pipes without digging. The CIPP method includes fixing a pipe from the inside by utilizing an unique material, which treatments over time, creating an also stronger pipeline throughout its process. While Pipe Relining is a great approach for pipeline repair, only a professional plumber can advise this damage repair technique.

Pipeline relining is unarguably a much better option contrasted to the traditional excavating technique. Closely observing the degree of pipeline damage is the initial step in pipeline relining.|

Intro

Repairing busted water pipes does not require excavating deep into your sewer lines and also attempting to change them anymore. Well, Pipeline Relining, of course.

5 Benefits of Pipeline Relining

Pipe relining is unarguably a much better choice contrasted to the standard excavating approach. It comes with some benefits, which makes it a more suitable option for all pipeline repair service conditions. These are some of the advantages of pipe relining;

The expense of pipeline relining is relatively low. Since no concrete penetration or trench digging is called for, you do not need to bear the cost of durable tools, re-filling trenches, and cleaning up the work area.

Relining takes little time to be completed. No added workforce is required and the whole process is easy, especially when it is being done by a professional plumbing solution. Managing hard to reach locations is also less complicated utilizing this approach.

The resin provides an extra finish for your weak pipes, leaving you with a two-in-plumbing system. The epoxy material often tends to be more powerful than the initially mounted pipe.

Unlike the standard trench excavating procedure, the chances of crashes caused by a disrupted floor surface area are dramatically decreased. Owners can relocate openly without disturbing the repair work procedure and vice versa.

The epoxy lining has a smooth surface area and also is devoid of obstructions that decrease the flow of water. After relining your water pipes, be anticipating a far better as well as smoother water flow.

Just How is Pipe Relining done?

Prompt pipeline repair is important in reducing the strength of the damages. The bright side is you can obtain your pipes taken care of in the space of 24 hours by simply connecting to our emergency plumbing solutions. The whole procedure is quick and also not as difficult as the traditional repair service procedure.

Here is a detailed process in relining of pipes;

Very closely observing the extent of pipeline damage is the very first step in pipeline relining. The Forced Electron Leak Place devices is used to very closely assess your plumbing system for problems and also blockages. By doing this, generating a solution is possible.

The length of your pipelines is then loaded with epoxy resin, which forms the stronger pipeline after curing. When dealing with T-sections, this step obtains harder.

The pipeline is cleaned up and all blockages eliminated to enable very easy water flow. Later, the pipe wall surfaces are prepared for resin application using a high-pressure water jet.

Treating can be carried out in 2 methods; leaving it to cure by hand or speeding up the process by using hot water. Either approach works - it simply depends on exactly how rapidly you desire the lining treated.

Our pipeline relining solutions makes certain that all relined pipes are fully checked utilizing a drainpipe examination camera. The final evaluation consists of screening to see if relined pipelines are totally sealed.

Joints are eliminated easily utilizing robot cutters. Examination pits can just be reduced using surface-level cutters or mills.

What is Pipeline Relining

Pipeline Relining is a way of fixing broken water pipelines without excavating. While Pipeline Relining is a fantastic approach for pipeline repair, just a professional plumber can advise this damages fixing approach.

The secret to reliable Pipeline Relining is creating a more powerful pipe by infusing resin in the harmed pipeline using a resin felt tube. Forming a stronger pipe is only possible when the material treatments, lasting for a very long time.

Final Decision

You can never go wrong with pipe relining. Saving all that money and energy spent on digging trenches sure really feels great. Do not wait to call our professional pipeline relining solution that keeps your entire plumbing system in the very best condition possible.

Remember, acting promptly is the only means to reduce the result of your pipeline damage. More damage means more expense to incur.

Pipeline relining is unarguably a better alternative contrasted to the conventional excavating approach. Carefully observing the degree of pipeline damage is the very first step in pipeline relining. Pipe Relining is a method of fixing broken water pipelines without excavating. The CIPP technique includes fixing a pipe from the within by making use of a special resin, which treatments over time, developing an also more powerful pipe during its procedure. While Pipeline Relining is a great approach for pipeline repair service, only a professional plumber can advise this damages repair work approach.}

When You Should Choose Pipe Relining

There are a number of reasons why you should consider pipe relining for your next job:

If your pipes are positioned down an embankment, underneath buildings, driveways or landscaping the cost of excavation (and replacing) these areas can be prohibitive, relining will likely be the answer. Overall, pipe relining comes with fewer expenses. Less labour, less parts, less repair to surrounding areas and less equipment. Pipe relining is nearly always quicker! It takes time to excavate (and potentially rebuild) – with pipe relining this isn’t going to be a worry! Excavating a large area can be dangerous. When large machinery becomes involved the risk of injuries on your site increases. And spare a thought for your team who need to continue working everyday with that noise in the background! Reduce your environmental impact with trenchless relining. Large excavation and construction works come with an increased carbon footprint. Pipe relining is a simpler and less invasive process with less impact. Stress less with pipe relining. Ongoing construction can be a nightmare to a business and its employees! I’m sure we can all agree that avoidable construction should be avoided at all cost! https://www.emuplumbing.com.au/pipe-relining-vs-pipe-replacement/

Hopefully you enjoyed our excerpt about What is Pipe Relining. Thanks so much for finding the time to read our piece. Sharing is nice. You just don't know, you could be helping someone out. Thanks a lot for taking the time to read it.

Visit Homepage